ANULON-92 Polypropylene

ANULON-92 Polypropylene

possesses the most valuable property which is its versatility. It can be tailored to many fabrication methods, such as, welding, machining, bonding and thermoforming for wide range of applications in chemical process pollutioncontrol, effluent handling equipment, food & beverage industries etc. to name a few. Due to its typical features, such as, lowest specific weight, high tolerance to impact and abrasion, excellent chemical resistance at elevated temperarures, UV resistance, non-adherence, non-toxic and moderate cost, ANULON-92 is an ideal material. ANULON-92 GL (Glass Lined) Sheets retain the general characteristics of Polypropylene. When laminated with woven polypropylene and fibre glass on one side, it is used for lining of tanks and vessels and for reinforcement with FRP.

ANULON-92 Polypropylene

possesses the most valuable property which is its versatility. It can be tailored to many fabrication methods, such as, welding, machining, bonding and thermoforming for wide range of applications in chemical process pollutioncontrol, effluent handling equipment, food & beverage industries etc. to name a few. Due to its typical features, such as, lowest specific weight, high tolerance to impact and abrasion, excellent chemical resistance at elevated temperarures, UV resistance, non-adherence, non-toxic and moderate cost, ANULON-92 is an ideal material. ANULON-92 GL (Glass Lined) Sheets retain the general characteristics of Polypropylene. When laminated with woven polypropylene and fibre glass on one side, it is used for lining of tanks and vessels and for reinforcement with FRP.

Exceptional wear and abrasion resistance

Excellent corrosion resistance

Low weight

Low coefficient of friction

Very good toughness and resilience

Outstanding resistance to repeated impacts

Low noise factor

Self Iubricating

Easy machinability

Economical compared to many alternatives

ANULON-92 Polypropylene (pp) Sheet

ANULON-92 Polypropylene (pp) Extruded Sheet

ANULON-92 Polypropylene (pp) Compressed Sheet

ANULON-92 Polypropylene (pp) Block

ANULON-92 Polypropylene (pp) Rod

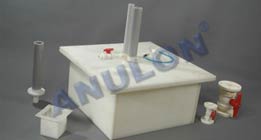

ANULON-92 Polypropylene (pp) Pipe

ANULON-92 Polypropylene (pp) Pipe Fitting

ANULON-92 Polypropylene (pp) Fabricated Component

ANULON-92 Polypropylene (pp) Fabricated Tank

ANULON-92 Polypropylene (pp) Nalvel

ANULON-92 Polypropylene (pp) Moulded Component

ANULON-92 Polypropylene (pp) Welding Rod

(with IZOD notch)

D- 256

Kg em/em2

respect to dry steel

0.50